What is OneStep?

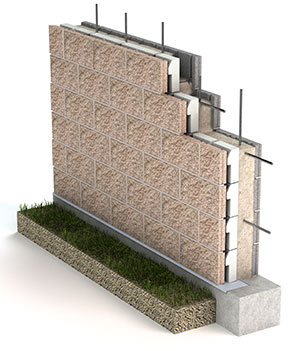

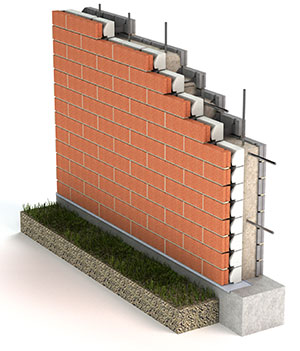

OneStep is a hybrid design that blends unit masonry construction and cast-in-place reinforced concrete into an efficient, single process, composite wall system.

OneStep walls have the outer appearance of conventional masonry surfaces, and are installed in mortar (using traditional methods) by masonry tradesmen. After a OneStep wall has been laid to a height of 4 feet with specified reinforcing, the interior cavity is filled with poured concrete. The end result is a very cost effective one operation 'sandwich wall', that has all the aesthetics of masonry and the strength of cast-in-place concrete with superior performance characteristics.

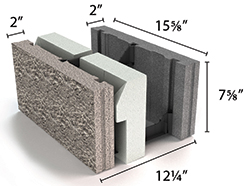

Block

12" Full Height Unit

*Additional

*Additional sizes available

Wall Assembly

12" Full Height Wall Assembly

12" Half Height Wall Assembly

Benefits

Design Flexibility

Multiple colors, textures, and patterns available in assorted masonry faces.

Energy Efficiency

High Static R-values & dense thermal mass create R-22 to R-40 equivalency and reduced energy costs. Unique design creates total thermal break.

Mason Friendly

Lighter weight, ergonomically designed units, which can lead to increased productivity with less lost time due to back and hand injuries (a 12" OneStep unit 33" lighter than a standard 12" CMU).

Safety & Strength

Strength of reinforced cast in place concrete, four hour fire rating, withstands extreme wind loads, very high bullet & blast resistance. A 12" OneStep wall can support over 300,000 pound per LF.

Superior Sustainability

Simplicity of design saves natural resources, human resources, transportation & energy costs. Results are quiet bulidings, improved air quality, a safe environment and life cycle savings.

Value

Fewer products, trades, and steps result in lower construction costs.

FAQ's

Q: What does CFMU stand for?

A: CFMU stands for Concrete Form Masonry Unit (OneStep).

Q: Will the units arrive on the job site completely assembled or will the mason have to assemble them in the field?

A: The units will arrive completely assembled with the insulation installed. However, a mason can easily snap on a face shell in the field if necessary.

Q: What sizes of units are available?

A: The OneStep unit is available in 4" high units with 16" long faces, with a through-wall thickness of either 12" or 16"; or 8" high units with 16" long faces, with a through-wall thickness of either 12" or 16".

Q: What shapes are available?

A: The OneStep wall system consists of all of the shapes needed to complete a typical installation application, which are as follows: L-Corner units, Full Stretchers, 1/2 and 3/4 Stretchers, Full and Half Jambs.

Q: Is the OneStep Building System load bearing?

A: Yes, the OneStep system is structurally the same as a reinforced, cast in place concrete wall.

Q: What finish options are available for the OneStep unit?

A: All standard finishes are available. Specialty finishes are also available (please contact us regarding particular finishes that you may desire).

Q: What product should I use to clean and/or seal the product?

A: The recommended products for cleaning and sealing OneStep are Custom Masonry Cleaner and Custom Masonry Sealer.

Q: Is the OneStep unit like an ICF (Insulated Concrete Form)? If not, how do they differ?

A: OneStep and ICF are similar in that they are both 'Form' systems, and both have built in insulation. However, the OneStep system is superior to ICFs in many ways. OneStep units are finished interior and exterior when they are installed, ICFs are foam interior and exterior, and thus require additional materials and labor to finish (which means they have a much higher per square foot cost for most finishes). OneStep units have thermal mass to the interior, whereas ICFs have insulation between the buildings interior and the concrete mass- thus OneStep units have far greater energy heating/cooling savings, and can utilize a smaller HVAC system which means lower up front costs. OneStep units have a built in air/weep cavity and thus have vastly superior resistance to moisture and water penetration through the building envelope.

Distributors

Serving all of WISCONSIN

Serving all of NORTH DAKOTA

& SOUTH DAKOTA

Serving all of IOWA

Serving all of E MISSOURI, SW ILLINOIS

& W KENTUCKY

Serving all of ALASKA

Serving all of N & E ILLINOIS

Serving all of W MISSOURI, KANSAS, OKLAHOMA & ARKANSAS

Serving all of IOWA & W ILLINOIS

Serving all of NORTH CAROLINA

& SOUTH CAROLINA

Copyright 2017 OneStep Building System