What is OneStep?

High Performance Buildings...OneStep Construction

OneStep is a hybrid design that blends unit masonry construction and cast-in-place reinforced concrete into an efficient, single process, composite wall system.

The patented OneStep design:

- Uses masonry 'face shells' to create a permanent concrete form system

- Breaks the 'thermal path' through a block or concrete wall

- Utilizes built-in rigid insulation panels to create an insulating 'envelope'

- Provides an integrated 1" air space/weep cavity

OneStep walls have the outer appearance of conventional masonry surfaces, and are installed in mortar (using traditional methods) by masonry tradesmen. After a OneStep wall has been laid to a height of 4 feet with specified reinforcing, the interior cavity is filled with poured concrete. The end result is a very cost effective one operation 'sandwich wall', that has all the aesthetics of masonry and the strength of cast-in-place concrete with superior performance characteristics.

Designed to provide improved performance & economy

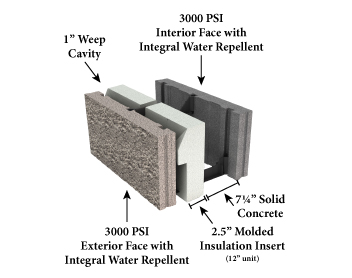

A cross section of a OneStep 12" consists of a 1 5/8" to 2 1/4" thick exterior face shell; a 1" air/weep cavity, a 2" thick rigid insulation panel; a 5 3/4" concrete filled cavity, and a 1 5/8" to 2 1/4" thick interior face shell. The union of the poured concrete with the interior face shell creates a solid concrete structural member that is 7 1/4" to 8 1/8" thick, and is designed to incorporate a wide variety of reinforcing options.

OneStep achieves superior energy efficiency through a unique design that eliminates the conduction of moisture, air, and heat through the wall.

The system provides the following attributes:

- High R-value insulated envelope

- High thermal mass value

- 1" air space

Excellent Economics

Although OneStep is a high performance wall system, it is more economical than many other building systems.

* OneStep is a 'one trade' wall system. As the masonry contractor installs and grouts

the units, the finished wall is complete on both sides, eliminating the need for any other trades.

* OneStep face shells can be produced 2 to 3 times faster than conventional block.

* OneStep is ergonomically designed for the mason tradesmen. The center handle of the unit is designed to fit comfortably in the mason's hand, and is balanced over the index and middle fingers helping to reduce stress on the hand and wrist. OneStep is also much lighter than standard block (a 12" x 8" x 16" OneStep unit weighs 26 lbs. vs. 55 lbs. for a traditional 12" unit). These factors speed the construction process, lessen fatigue, and reduce losses due to injuries and down time.

Design Flexibility

Available in all standard masonry finishes and sizes

OneStep can utilize a wide variety of material as 'veneer member', or face shells, including concrete block, clay brick, quarried stone, and faux concrete and stone products. These materials are available in a multitude of colors, textures and design patterns. The face shells are made independent of each other giving the designer a great multitude of design options. Additionally, OneStep units can be laid in many different bond patterns, including running, common, Flemish and stack bond, as well as in modular and Ashlar stone patterns. Never before has a wall system offered so much inherent flexibility to the design professional.

Environmental Friendliness

The OneStep Building System has been designed and developed to be an environmentally sustainable product.

Consider the following list:

Energy Efficient

High R-values and thermal mass benefits.

Recycled Materials

OneStep walls can utilize large quantities of post consumer/industrial 'waste' materials. OneStep walls can utilize large quantities of recycled materials.

Longevity

OneStep buildings are made to last for centuries.

Noise Pollution

The OneStep wall is extremely quite with high STC (Sound Transmission Class) ratings.

Environmental Impact

OneStep units are made of sand, gravel, cement and recycled materials.

Local Manufacturing

Reducing the impact of product transportation.

Superior Strength

Although the outer surface of a OneStep wall consists of masonry veneer members, the internal structure consists of cast-in-place concrete. By utilizing the ultimate strength design of concrete, OneStep structures can be designed to withstand hurricane and tornado force winds, earthquakes, and explosive shock. Additionally, the composition of OneStep makes it a 4-hour fire wall assembly.

Back to top

Although a wall built with the OneStep Building System looks like a masonry wall, the workhorse of the CFMU is the concrete fill and steel reinforcement bars in the inner wall cavity.

Copyright 2019 - OneStep Building System - One Product, One Trade, One Step!